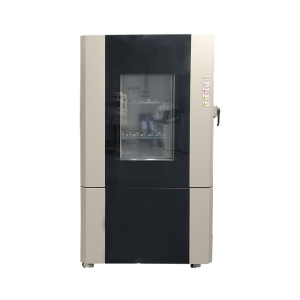

ZH-CJ80 Suspended basket type Temperature shock Test chamber

Free Shipping

For all orders over $200

Solution

Provide specific feasible solutions

Distribution

Supply product distribution

Hotline Order:

+86 400-816-6687

+86 13316038150

| 1. Product name | |

| 1.1. Impact box

1.2. Model |

Hanging basket type temperature shock test chamber

ZH-CJ80 |

| 2. Specimen limitations | |

| 2.1. This test equipment prohibits

|

Testing and storage of flammable, explosive, and volatile substance samples

Testing and storage of corrosive substance specimens Testing or storage of biological specimens Testing and storage of specimens from strong electromagnetic emission sources |

| volume, size and weight | |

| 2.2. Nominal volume

2.3. Bassinet size 2.4. Dimensions 2.5. weight |

80L

W400XH500XD400 mm W860XD2040XH2050mm Approx. 820Kg |

| 3. performance | |

| 3.1. Test environmental conditions

3.2. Test Method: |

The ambient temperature is 5~35°C

Relative humidity ≤ 85%RH 气压(86~106)kPa There are no specimens in the test chamber GB/T5170.2-2008 Temperature test equipment |

| 3.3. Preheat temperature range

3.4. Pre-cooling temperature range 3.5. Carrycot changeover time 3.6. Temperature fluctuations 3.7. Temperature deviations 3.8. Impact temperature range 3.9. Hot punch recovery time 3.10. Cold flush recovery time 3.11. load |

Preheating temperature in high temperature area: +50~200°C

Pre-cooling temperature in low temperature zone: -70~-10°C ≤10s (screw lifting). ≤ 1.0 °C (≤± 0.5 °C, according to GB/T5170-2008). ±2.0℃ -40~+150℃ -40→+150°C ≤5min, no load, holding time 30min +150°C→-40 ≤5min, no load, holding time 30min not |

| 3.12. Meet the test criteria | GB/T 2423.1-2008 Test A: Low temperature test methods

GB/T 2423.2-2008 Test B: High temperature test method GJB 150.3-2008 High Temperature Test GJB 150.4-2008 Low temperature test (The load per cubic meter is not more than 35kg/m3 of the heat capacity of the steel) |

| 4. Structural features | |

| 4.1. Thermal insulation envelope structure

|

Outer wall material: 1.2m double-sided electrolytic plate, surface spraying

Inner wall material: 1.0 rust steel plate SUS304 Box insulation material: foaming material Door insulation material: foaming material Vertical temperature zone (high temperature chamber, low temperature chamber) temperature shock chamber arranged vertically up and down, the sample is placed in the carrying basket and connected together by the screw rod and the sample basket) to move between the high temperature chamber and the cryogenic chamber. The box is an integral structure (non-assembled plate structure), and the outer wall is sprayed cold-rolled steel plate. The wall of the studio is SUS304 high-quality stainless steel plate, smooth and flat, the thermal insulation material is stress-resistant insulation material, and the inner wall of the unit part has sound absorption and noise reduction measures. |

| 4.2. Air conditioning channels | Centrifugal fans: 2 pcs

Heaters, evaporators (and dehumidifiers), water supply and drain outlets, dry bulb temperature sensors |

| 4.3. The laboratory body is equipped as standard

|

Observation window: 1 transparent electric heating film hollow tempered glass (located on the door)

Visible Range: None; Includes the scope of the lamp occlusion (see the outline drawing of the device for details). Lead hole: φ50mm 1 (located at the top of the box). Sample holder: 2 layers of stainless steel sample holder, bearing weight (uniform distribution): 20kg/layer Lighting: 7W-24V Mobile casters: 4 pcs |

| 4.4. door | Single-opening hinged door (left hinge, right handle)

Lighting: 5W Anti-condensation electric heating installation for window frames/door frames |

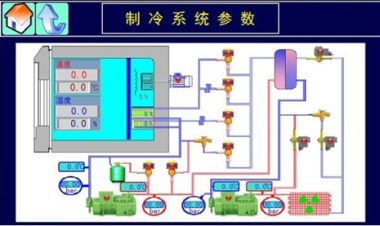

| 4.5. control panel

|

Temperature-controlled display

Over-temperature protection setting device Emergency stop switch Running indicator Fault indicator buzzer |

| 4.6. Mechanical room | Refrigeration units

Drain connections Fans Power distribution control cabinets |

| 4.7. Lifting mechanism | Pneumatic chain lifting is adopted, which is stable lifting, high safety and long life |

| 4.8. Basket | The basket is made of thickened stainless steel plate full welding, riveting, and protective fences are installed around it to prevent it

Sample drop, see figure below:

|

| 4.9. Power distribution control cabinets

|

Cooling fan

Switchboards 232 Physical Interfaces |

| 4.10. heater

|

316 stainless steel armored heater

Heater control mode: Constant periodic pulse width adjustment without contact, SSR (Solid State Relay) |

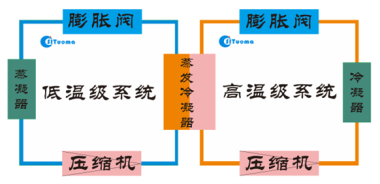

| 5. Refrigeration system | |

| 5.1. How it works | Water-cooled mechanical cascade refrigeration mode

|

| 5.2. Refrigeration compressors | Scroll shrinking machine |

| 5.3. evaporator | Fin heat exchanger |

| 5.4. condenser | Shell-and-tube heat exchangers/brazed plate heat exchangers |

| 5.5. Throttling device | Thermostatic expansion valves, capillaries |

| 5.6. Chiller control method

|

The PLC (Programmable Logic Controller) of the control system automatically adjusts the operating conditions of the chiller according to the test conditions

The thermostatic expansion valve controls the compressor return air cooling circuit Automatic hot gas valve energy regulation circuit Use a thermostatic expansion valve to adjust the cooling circuit with PID

|

| 5.7. Refrigerants | The R404A ozone depletion index is 0

The R23 ozone depletion index is 0 |

Zhipinhui after-sales service

Equipment after-sales policy:

*Equipment warranty period: One Year

*After sales hotline: 4008166687

1. Our company has assembled a team of experienced on-site engineers and senior technicians who can respond promptly to any equipment issues and provide after-sales maintenance.

2. Within one week of the delivery of the new product, our after-sales technical department staff will provide installation and after-sales training for the equipment at the customer’s location based on the contact information and address provided by the customer.

3. All complaints related to product quality will be responded to within 1 hour. Within 3-5 hours within the province and 24-48 hours outside the province, the customer will arrive at the scene and determine the handling measures based on the complaint situation, and carry out after-sales maintenance.

4. To better address customers’ difficulties and concerns, our company promises that all maintenance personnel will be on call.

5. Any costs related to product quality during the shelf life will be borne by our company.

6. During the warranty period, we will provide free repairs due to improper use by your side or natural environment. The materials and accessories used for repairs will only be charged at cost price.

Related products

-

Temperature and humidity test chamber

Rated 0 out of 5(0) -

ZHHW-85 Constant Temperature and Humidity Test chamber

Rated 0 out of 5(0)