Electronic ice liner life test bench

Free Shipping

For all orders over $200

Solution

Provide specific feasible solutions

Distribution

Supply product distribution

Hotline Order:

+86 400-816-6687

+86 13316038150

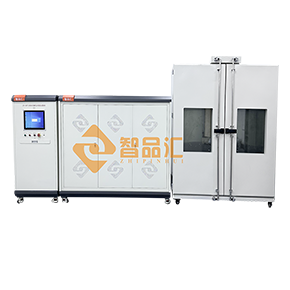

Electronic Ice Tank Life Test Bench (15 stations)

- Basic requirements: It is suitable for durability testing of cold galleries of tea bar machines, desktop machines and pipeline machines;

- Equipment function: In accordance with the technical requirements of the relevant regulations, the durability of the cold tank of the tea bar machine, desktop machine and pipeline machine is tested

test, meet the capacity of 6000 cycle life;

Meet the requirements of the enterprise standard:

- 3. Test content: It is mainly used for durability testing of cold galleries of tea bar machines, desktop machines and pipeline machines; (Wind turbine life test additional.)

Equipped with high temperature chamber, 6 fans can be tested at the same time)

- Technical Parameters

4.1 Station: 15 stations, can work independently, with the same source input, with ball valve independent input;

4.2 Water tank: 100L water tank, material 304, thickness ≥ 1.2mm;

4.3 Water supply pressure: 0.05~0.4MPa adjustable;

4.4 Pressure sensor: 0~0.6MPa, brand requirements: GE, accuracy requirements±0.2%FS;

4.5 Water output temperature: 0-120°C, accuracy: 0.5% F.S.;

4.6 Inlet water temperature: 25°C±5°C, use air-cooled constant temperature unit;

4.9 Equipment control: Achieve 2 situations: 1. When the refrigeration temperature of the cold tank reaches the set value, the cold tank fan stops working, and the equipment

Open the water discharge valve, the water discharge time can be set 0~999s, after the water discharge is over, open the equipment water valve, the water supply time can be 0~999s

Set it, then restart the cold tank to start the refrigeration work, and repeat the cycle. 2. When the refrigeration temperature of the cold tank reaches the set value, the cold tank

When the fan stops working, the device opens the water replenishment valve and the water discharge valve at the same time, and the device detects the water temperature and stops when it reaches a certain set temperature

Replenish and drain water, then restart the cold tank to start the refrigeration work, and repeat the cycle.

4.10 Total water supply flow: 0~10L/min; Water supply pressure: 0.05~0.2MPa

4.11 Station voltage test: DC (0~60)V, accuracy ± 0.1V;

4.12 Station power test: input the rated power of the product (usually: 100W), and use the power meter to test whether it meets the product

Rating, industrial computer records data, display accuracy 0.1W;

4.13 High temperature chamber requirements:

4.13.1 Temperature range: RT+10°C~200°C;

4.13.2 Specifications of the cavity: length 455mm * width 430mm * height 510mm;

4.13.3 Temperature fluctuation: ±1°C;

4.13.4 Temperature uniformity: ±1.5% (test point is 100°C);

4.13.5 Volume: 100L;

- Comprehensive performance of the equipment

5.1 Constant temperature water tank (supporting chiller and heating control): Equipped with a 100L water tank, made of 304, using high-precision temperature

The sensor feeds back the temperature value, and when the temperature exceeds the set range, and the overtemperature time also reaches the set value, the refrigeration and system can be automatically started

Hot, with a thermometer to display the current sink temperature in real time, the inside of the tank has a float switch with a high and low water level alarm, in high water

Disconnect the water inlet valve to stop adding water, and open the water inlet valve to add water to the water tank when the water level is low;

5.2 Constant pressure water supply: using a constant pressure water supply pump, the pressure is set to the value that needs to be used, providing 15 stations of water flow;

5.4 Life test: through the tooling (clamping the cold tank according to the actual working conditions) fixed → control cabinet computer interface set parameters→

Set the number of tests→ click to start the test→ and finally determine whether the product still meets the performance requirements;

5.4 Console: Using PLC control, select the test items on the computer display screen and enter the corresponding test parameters, and the interface displays each

information such as water outlet temperature and ambient temperature of each station; Computer control records data, stores and generates reports;

5.5 Safety protection: the water tank has the function of overflow, leakage and low water level protection; Protective door plus travel switch.

- Other Requirements:

6.1? The material of the equipment pipe is made of 304 stainless steel.

Zhipinhui after-sales service

Equipment after-sales policy:

*Equipment warranty period: One Year

*After sales hotline: 4008166687

1. Our company has assembled a team of experienced on-site engineers and senior technicians who can respond promptly to any equipment issues and provide after-sales maintenance.

2. Within one week of the delivery of the new product, our after-sales technical department staff will provide installation and after-sales training for the equipment at the customer’s location based on the contact information and address provided by the customer.

3. All complaints related to product quality will be responded to within 1 hour. Within 3-5 hours within the province and 24-48 hours outside the province, the customer will arrive at the scene and determine the handling measures based on the complaint situation, and carry out after-sales maintenance.

4. To better address customers’ difficulties and concerns, our company promises that all maintenance personnel will be on call.

5. Any costs related to product quality during the shelf life will be borne by our company.

6. During the warranty period, we will provide free repairs due to improper use by your side or natural environment. The materials and accessories used for repairs will only be charged at cost price.

Related products

-

Static pressure burst testing system for the entire water purifier

Rated 0 out of 5(0) -

Heat exchanger test bench

Rated 0 out of 5(0) -

Booster pump performance test bench

Rated 0 out of 5(0) -

Dc pump life test bench

Rated 0 out of 5(0)