Building a "Neural Network" in a Smart Laboratory

Make testing data more convenient and scientifically traceable

Ultimately, the use of a humidity chamber is a cornerstone of a robust Quality Assurance (QA) program. It moves quality control beyond simple functional checks and into the realm of predictive failure analysis. By intentionally stressing products in a humidity chamber, manufacturers can uncover hidden flaws that would not appear under normal inspection. This proactive approach to quality […]

Many industries are governed by strict international standards that mandate environmental testing. Regulatory bodies and industry consortia (such as ISO, ASTM, IEC, and MIL-STD) require products to pass specific tests to ensure safety, quality, and interoperability. A humidity chamber is the standardized apparatus used to perform these tests, ensuring that results are consistent, repeatable, and comparable across […]

The performance of adhesives, coatings, and finishes is highly dependent on environmental conditions, making the humidity chamber an indispensable tool. High humidity can prevent adhesives from curing properly or weaken their bond over time. Paints and protective coatings may blister, peel, or lose their color when exposed to moisture and heat. By subjecting bonded assemblies or painted […]

The core reason for using a humidity chamber is to accelerate the aging process. It is impractical and costly to test a product’s 10-year lifespan by leaving it in a natural environment for a decade. A humidity chamber can replicate the damaging effects of long-term humidity exposure in a significantly shorter time by applying extreme, yet controlled, stress. This […]

The humidity chamber plays a pivotal role in determining the shelf life of products and the effectiveness of their packaging. Pharmaceuticals, foods, and specialty chemicals can degrade when exposed to moisture, losing potency or becoming unsafe. The packaging itself—whether blister packs, bottles, or sealed bags—must provide an effective moisture barrier. By storing these products in a humidity chamber under […]

A critical application of the humidity chamber is in the prevention of corrosion and electrical failures. Metals are highly susceptible to oxidation and corrosion when exposed to moisture, especially when combined with high temperatures. Similarly, electronic components and circuit boards can suffer from condensation, leading to short circuits, current leakage, and the growth of conductive metal filaments […]

Products are tested in a humidity chamber to verify the integrity and dimensional stability of their constituent materials. Many materials, such as plastics, woods, composites, and textiles, are hygroscopic, meaning they absorb moisture from the air. When this happens, they can swell, warp, or change their physical properties. For example, a wooden door must not warp in […]

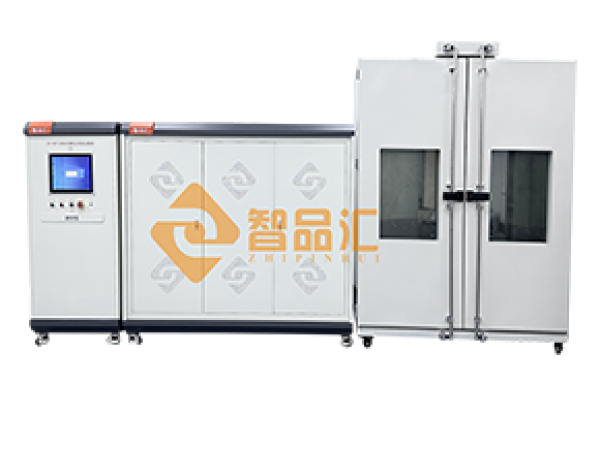

A humidity chamber is an essential piece of testing equipment designed to simulate a wide range of atmospheric conditions by precisely controlling temperature and relative humidity. Its primary function is to create a controlled environment where products and materials can be subjected to high humidity, low humidity, and cyclic variations. This testing is crucial because real-world environments […]

Recent Post

Tags

Historical Articles

- October 2025 (9)

- September 2025 (65)

- May 2025 (15)

- April 2025 (20)